Workplace safety is paramount, particularly in industries where employees deal with hazardous materials or work-alone in remote areas. In recent years, there has been a rapid rise in demand for safety solutions that cater to gas detection and lone worker safety as organizations recognize that safeguarding employees not only improves productivity but also significantly reduces the risks and liabilities associated with accidents.

At Blackridge Solutions, we understand these concerns and have dedicated ourselves to

providing innovative solutions to ensure the utmost safety at the workplace.

In our blog, we focus on gas detection and work-alone safety topics, specifically addressing how

our innovative and award-winning solutions protect employees in various industries and reduce

business risks. In particular, our articles explore how Blackridge Solutions utilizes advanced

technology to make workplaces safer for employees, whether they are working alone or with

hazardous gases.

Advanced Gas Detection Solutions for a Safer Work Environment

1. The Importance of Accurate and Reliable Gas Detection

To ensure a safe and healthy work environment, especially in industries where hazardous

gases are present, it's essential to prioritize and invest in accurate and reliable gas detection

systems. Traditional gas detectors have limitations, such as false alarms, inaccurate readings,

or slow gas detection responses. These issues can create unnecessary delays, reduce

productivity, and, more importantly, undermine employees safety.

At Blackridge Solutions, we offer state-of-the-art gas detection equipment that overcomes these

limitations and provides an unmatched level of accuracy and reliability. By employing cutting-

edge technology such as real-time data analysis and advanced sensor systems, we ensure our

detectors quickly and accurately identify hazardous gases for maximum workplace safety.

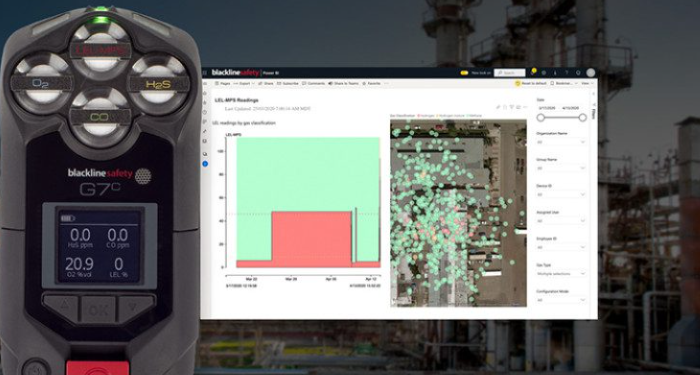

2. Monitoring and Reporting: A Critical Aspect of Gas Detection

To address the challenges of hazardous gas detection, Blackridge Solutions provides gas

detection systems that not only detect hazardous gases but also monitor and report the data in

real time. This approach ensures both employers and employees are aware of their exposure

levels and can take the necessary steps to avoid unsafe conditions.

Our advanced gas monitoring systems integrate seamlessly with our range of detectors,

allowing companies to monitor data and create a customized plan of action in emergency

situations or during routine operations. The real-time data generated by our devices not only

helps maintain a safe working environment but also aids in ensuring regulatory compliance

required in many industries.

Lone Worker Safety: Empowering Employees and Reducing Risk

1. The Unique Challenges of Lone Worker Safety

Ensuring the well-being of employees working alone can be challenging, primarily because

traditional safety measures may not be effective in mitigating the risks they face. When working

remotely or in isolated environments, threats can range from physical injury or sudden health

concerns to environmental hazards and security risks. These challenges call for a tailored

approach that addresses the unique aspects of each worker's situation.

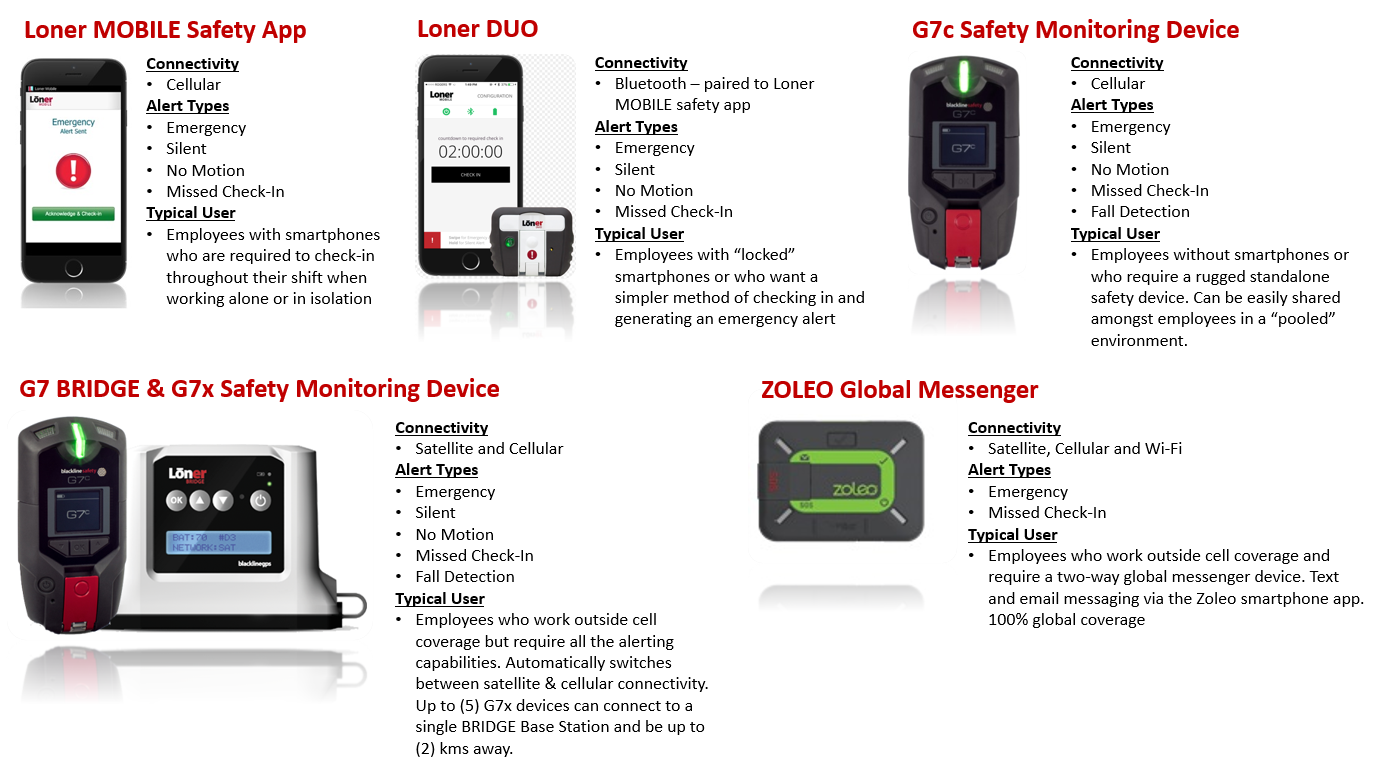

Blackridge Solutions recognizes the need for specific safety measures for lone workers and

provides a range of tools and equipment designed to empower these employees in maintaining

their safety. Our award-winning work-alone safety solutions drivers are specifically designed to

support lone workers in any industry.

2. Real-time Monitoring and Communication for Lone Workers

Communication is vital for lone workers in ensuring timely assistance during emergencies. Our

advanced monitoring devices address this concern by enabling seamless communication

between remote workers and their support teams. Equipped with GPS tracking, two-way voice

and text communication, and safety monitoring features, these devices make it easier for

organizations to track employees' locations and offer assistance when it is needed the most.

3. Alerts and Notifications for Extra Peace of Mind

Our work-alone safety solutions further improve lone worker safety by providing alerts and

notifications. These devices can automatically detect when an employee has not checked in

during a pre-determined monitoring schedule or if a fall is detected. Additionally, employees can

easily trigger an alert to notify their support team in case they need assistance, ensuring that

help will be on the way before the situation escalates.

Blackridge Solutions: Embracing Technology for a Safer Work Environment

As industry leaders in gas detection and work-alone safety, Blackridge Solutions is committed to

embracing and utilizing advanced technology to deliver the best possible solutions for our

clients. By continually researching and implementing new innovations, we aim to create an

environment where employees feel confident in their safety and where businesses can mitigate

risks and liabilities associated with accidents.

Some of the advanced technologies employed in our products include GPS location tracking,

real-time data reporting, wireless connectivity, and mobile app integration. These features

increase the efficiency and reliability of our gas detection and work-alone safety devices and

create a safer and more connected work environment.

Final Thoughts: Investing in a Safe and Successful Future

At Blackridge Solutions, investing in advanced gas detection and work-alone safety solutions is

not only critical for employee well-being but also essential for creating a successful and

sustainable business. By providing cutting-edge devices and services, we've made it our

mission to ensure that organizations minimize potential risks and liabilities for their employees

and operations.

Through our commitment to innovation and superior product quality, along with our dedication to

workplace safety, we provide businesses with the tools and knowledge they need to create a

thriving professional landscape where employees feel protected, valued, and supported.

Learn more about gas detection and lone worker monitoring systems by giving us a call today! (778) 686-5799 or [email protected]

RSS Feed

RSS Feed