growth for the area. However, these jobs often come with inherent risks. Workers in the oil and

gas industry face numerous hazards daily, making it one of the most dangerous industries to

work in.

In that regard, it's worth highlighting the five of the most common dangers Gulf Coast oil and

gas workers face, so you can have a better idea of how to mitigate these risks.

1. Confined Space Entries (CSEs)

A confined space is one with limited access or egress, not designed for continuous occupancy,

and can pose a risk to workers health and safety. Examples of confined spaces in the oil and

gas industry include storage tanks, pipelines, and vessels.

Working in confined spaces exposes workers to a range of hazards, such as toxic gases,

oxygen deficiency, flammable or explosive atmospheres, and physical risks such as falling or

entrapment

.

To reduce the risks often associated with confined space entries, employers should:

- Implement a robust confined space entry program

- Train workers on confined space hazards and safe work practices

- Use appropriate personal protective equipment (PPE)

- Monitor the atmosphere in confined spaces before and during work

- Establish rescue procedures in case of emergencies

2. Lone Worker and Transportation Hazards

Working alone or in remote locations is common in the oil and gas industry. Lone workers are at

a higher risk of accidents, as they may not have immediate access to assistance in case of an

emergency. Additionally, traveling to and from worksites can expose workers to transportation-

related hazards, such as vehicle accidents, fatigue, and adverse weather conditions.

To minimize lone worker and transportation hazards, employers should:

- Develop a lone worker policy and emergency response plan

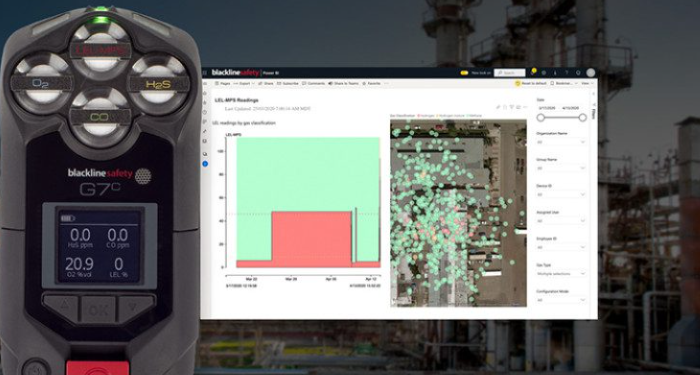

- Ensure workers have access to reliable communication devices

- Implement a check-in system to monitor the well-being of lone workers

- Provide training on safe driving practices

- Monitor and manage work hours to prevent fatigue

3. Evacuation Management

In the event of an emergency, such as a fire, explosion, or gas leak, workers must quickly and

safely evacuate the worksite. Evacuation management can be challenging in the oil and gas

industry due to the complexity and size of the worksites, as well as the presence of hazardous

materials

.

To improve evacuation management, employers should:

- Develop and regularly update an emergency response plan

- Train workers on emergency evacuation procedures

- Conduct regular emergency drills to ensure workers are familiar with evacuation routes

- and assembly points

- Install and maintain appropriate emergency equipment, such as fire extinguishers,

- alarms, and safety signage

4. Exposure to Hazardous Gases or Unsafe Oxygen Environments

Oil and gas workers are often exposed to hazardous gases, such as hydrogen sulfide, carbon

monoxide, and volatile organic compounds. Exposure to these gases can lead to respiratory

problems, chemical burns, and even death. Additionally, working in environments with

insufficient oxygen can cause asphyxiation.

To protect workers from hazardous gases and unsafe oxygen environments, employers should:

- Implement a comprehensive gas detection and monitoring program

- Train workers on the hazards of specific gases and how to use gas detection equipment

- Ensure that workers wear appropriate respiratory protection when necessary

- Establish emergency procedures for gas leaks or oxygen-deficient environments

5. Shutdowns and Turnarounds

Shutdowns and turnarounds are periods when oil and gas facilities are taken out of service for

maintenance, inspection, and repair. These periods can be particularly hazardous for workers,

as they may involve working at heights, heavy lifting, and exposure to dangerous substances.

To reduce risks during shutdowns and turnarounds, employers should:

- Plan and schedule shutdowns and turnarounds carefully to minimize risks

- Provide comprehensive training on shutdown and turnaround procedures

- Ensure that workers have access to appropriate PPE and safety equipment

- Establish clear lines of communication and coordination among workers, contractors, and management

The Bottom Line

Working in the oil and gas industry in the Gulf Coast region presents unique challenges and

hazards that must be managed to ensure the safety of workers. Ultimately, a culture of safety

and continuous improvement is essential for maintaining a safe and productive work

environment in this high-risk industry.

If you’re looking for a reliable and secure lone worker monitoring system, look no further than

BLACKRIDGE Solutions. Contact us today at [email protected] or (778) 686-5799 to learn more about our solutions and get started protecting your employees!

RSS Feed

RSS Feed